Stainless steel is trusted across construction, manufacturing, pharmaceutical, food, and processing industries because of its strength, corrosion resistance, and long service life. But the performance of stainless steel depends heavily on how it is produced and processed.

Understanding the stainless steel production process helps engineers, procurement teams, and project managers make better material decisions—especially when quality and reliability are critical.

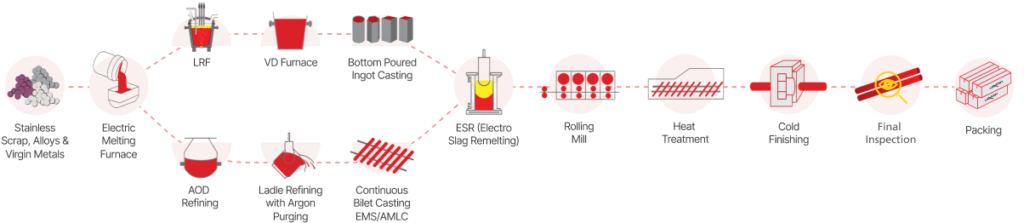

This blog explains the key stages of stainless steel production, as illustrated in the process flow, and why each step matters for industrial applications in Pakistan.

1. Raw Material Selection

The stainless steel production process begins with carefully selected raw materials. These typically include:

Iron ore or recycled steel scrap

Chromium (essential for corrosion resistance)

Nickel and other alloying elements (for strength and durability)

The correct balance of these elements determines the final grade of stainless steel, such as SS 304 or SS 316, which are widely used in Pakistan’s industrial and construction sectors.

2. Melting in Electric Furnaces

The raw materials are melted together in high-temperature electric furnaces. This stage ensures that all elements combine uniformly to form molten steel.

Precise temperature control and alloy composition are essential at this stage, as they directly affect:

Corrosion resistance

Mechanical strength

Chemical stability

This controlled melting process is a key reason stainless steel performs reliably in demanding environments.

3. Refining and Composition Control

After melting, the molten steel is refined to remove impurities such as excess carbon and unwanted gases. Oxygen and other refining techniques are used to achieve the required chemical composition.

This step ensures:

Compliance with international standards

Consistent material quality

Suitability for industrial, food-grade, and pharmaceutical applications

Proper refining distinguishes high-quality stainless steel from lower-grade alternatives.

4. Casting into Semi-Finished Forms

Once refined, the molten stainless steel is cast into semi-finished shapes such as slabs, billets, or blooms.

These forms serve as the base material for further processing and allow manufacturers to produce:

Sheets and plates

Pipes and tubes

Bars and structural sections

Uniform casting is critical for dimensional accuracy and mechanical consistency.

5. Hot Rolling and Forming

The cast stainless steel is then hot rolled at high temperatures. This process reduces thickness, improves surface quality, and enhances mechanical properties.

Hot rolling allows stainless steel to be shaped into:

Coils and sheets

Plates

Bars and sections

This stage gives stainless steel its strength and workability for industrial use.

6. Finishing and Surface Treatment

After rolling, stainless steel undergoes finishing processes such as:

Annealing

Pickling

Surface polishing

These treatments improve corrosion resistance, surface cleanliness, and appearance—especially important for hygienic and architectural applications.

7. Final Stainless Steel Products

The finished stainless steel is then converted into final products used across industries, including:

Stainless steel pipes and tubes

Sheets and plates

Flat bars, angles, and channels

Industrial-grade fittings

Each product is inspected to ensure it meets required standards and performance specifications.

Why the Production Process Matters for Buyers in Pakistan

For procurement teams and engineers, understanding the production process explains why not all stainless steel performs the same, even if it looks similar.

High-quality production ensures:

Better corrosion resistance

Longer service life

Reduced maintenance and downtime

Compliance with industrial and hygienic standards

This is especially important in Pakistan’s environments, where humidity, chemicals, and heavy usage are common.

Saify Iron & Cement Mart – Supplying Quality Stainless Steel You Can Trust

Saify Iron & Cement Mart supplies stainless steel products sourced from reputable manufacturers that follow controlled and standardized production processes.

Our product range includes:

Stainless steel pipes (SS 304 & SS 316)

Stainless steel sheets and plates

Flat bars, angles, and channels

Industrial-grade stainless steel fittings

We focus on quality, consistency, and suitability for Pakistan’s industrial, construction, pharmaceutical, and food sectors.

Conclusion

Stainless steel’s strength and reliability begin long before it reaches the job site. From raw material selection and melting to refining, rolling, and finishing, every production stage plays a vital role in determining performance.

By sourcing stainless steel produced under proper standards and supplied by a trusted distributor, businesses can ensure safer operations, longer service life, and better value.

Saify Iron & Cement Mart remains committed to providing dependable stainless steel solutions for Pakistan’s growing industrial needs.